⚙️ #15 Moto Suspension 101 🎾

Hi! It's been a month since so here's a quick update on Dust. Editions #12-14 covered the 3 founders. Since those posts we've held our inaugural F50 monthly Google Meet (second is this Friday), taken a small workshop space in Bend, and are working hard on Alpha prototypes.

The basic F50 concept is 50 bikes, 50 riders, and 50% off. Taking backers on a 20-month behind-the-scenes journey to bear witness as we develop the bike and brand from a completely clean sheet. F50 filled in 24 hours and 10x'ed our following, and there is a waiting list for the next 200 bikes. F50 has 55 members including a handful of athlete and expert ambassadors. We used the success of F50 to raise an Angel_1 pre-seed funding round of $0.4M from friends & family. We're grateful to each and everyone of the F50 members for helping get Dust airborne.

As a part of our general thesis on "Building in Public" and illuminating key areas associated with developing a performance oriented dirt bike, this month we will dive into suspension.

Technical Foundations

Suspension forms a critical portion of any vehicle's ability to traverse varied terrain at speed. With the primary aim of allowing for the bulk of the vehicle's mass to follow the smoothest path possible, an effective suspension manages the dynamic motion and terrain inputs using various spring and damping elements.

The specific performance objectives that a vehicle designer is looking to enhance with the design of a suspension system are:

- Traction

- Control

- Comfort

- Durability

While a simple rubber band may form an effective suspension for some of my favorite Lego monster truck build kits, there are myriad terms and variables that form the basis of the suspension mechanism. Some of these include: spring rates (determines force needed to move suspension), rebound and compression damping (the energy absorption capacity), travel (how much the wheel can move), stroke (amount the spring/damper compresses), sag (where in the travel the vehicle sits at rest), wheel path (what path the suspension traces in motion), and leverage rate/ratio (how much the wheel moves compared to the stroke).

Those elements are all wrapped around the global constraints of the vehicle design itself - size, weight, cost and complexity (assembly + serviceability).

Practical Application - Design & Integration

Now that we are past the foundational elements of the why and what for suspension design, lets zoom in on the how. How does a vehicle designer work with the available tools and methods to execute the best design for the use case?

At the heart of the problem space sit three primary areas where decisions must be made.

- The mechanism type

- The spring type

- The damper type

The Mechanism

For the purposes of this discussion, we will focus on the typical methods being deployed in the dirt bike market. Acknowledging the increasingly complex systems that are deployed in the bicycle and automotive segments, motorcycle suspension mechanism design typically boils down to whether the shock is located at the front or rear of the vehicle, and if the rear, whether the shock is directly driven by the swingarm or a system of moving components, called a linkage.

The front of the vast majority of motorcycles (nearly 100% of all off-road dirt bikes) utilize telescoping "forks" for the front suspension. These designs fully integrate the steering, spring, damper and structural elements into the front wheel mounting interface.

More interesting for this post is the rear of the bike, and the choice of mounting the shock directly to the swingarm, or onto a mechanism of linkages. Here, the decision can create vastly different riding experiences.

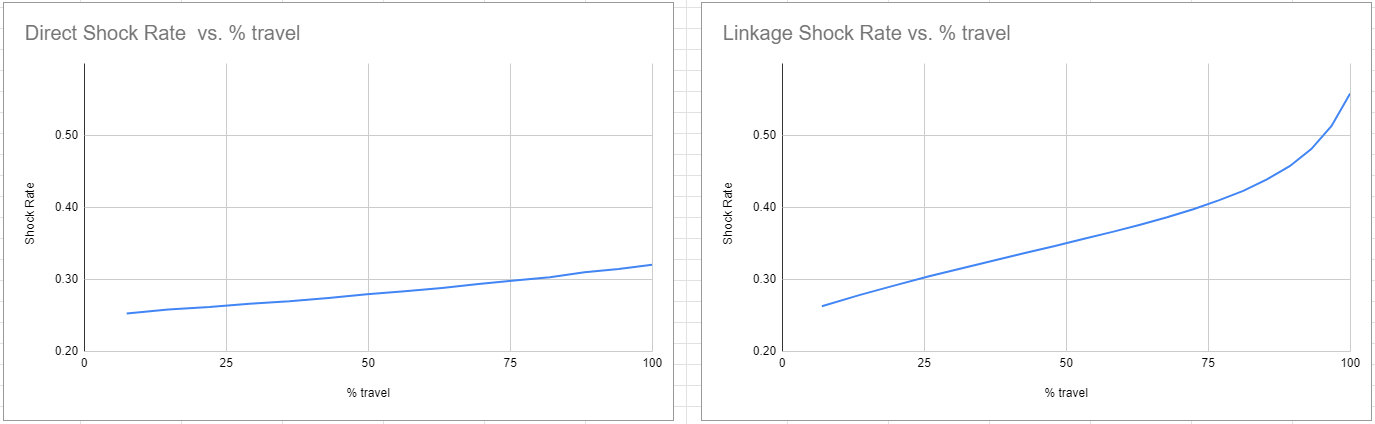

Typically, a direct mount design allows for a simpler mechanism, saving weight and complexity. However, this design, notably does not allow for significant tuning of the leverage ratio and the shape of the rate curve, ultimately meaning the design might not have the progressivity (ramping up of force through travel) necessary for the most hardcore applications. This necessitates the usage of progressively wound spring and damping systems with additional features to manage bottom-out forces. The nature of mounting directly to the swingarm also means the packaging options and size of the shock is much more limited.

The linkage driven design, by contrast, is highly tunable. The addition of a rocker and wishbone link allows for the designer to make minute changes to the characteristic of the motion ratio between the wheel and shock. Additionally, the shock placement can be adapted for various chassis designs, depending on the limitations around the drivetrain or vehicle layout. Because of the inherent tuneability of the design, there also exists a healthy aftermarket industry of tuners and component suppliers offering solutions to change the behavior of a given linkage design.

However, the extra tunability of a linkage design could become a curse. A poorly implemented linkage design could mean the vehicle suffers the worst of additional weight and complexity with poor suspension feel or performance. Numerous available bikes on the market exhibit these characteristics. Therefore a skilled engineering team and detailed test program is required to ensure the design fits the intended use case.

The Spring

Typically, for dirt bike usage, metallic coil springs are utilized because of their reliability, consistency and availability. A typical coil spring exhibits linear spring rate curves, meaning the force ramps up in direct proportion to the compressed distance. In the case of a direct-mount design, special progressively wound coil springs may need to be utilized. In order to adjust the suspension system for rider weight and application, balancing sag and bottom out characteristics, the rider may choose to adjust the pre-load of the coil, or purchase a coil spring of differing spring rate.

While air springs are much more common in the MTB world, there are various reasons their adoption has been much lower in the moto (and motorsport) world. Air springs function by having a sealed volume of air that is compressed as the shock travels through its stroke. The physics of compressing air in a volume dictates that there is a non-linear (re: progressive) nature to the design, which can be tuned using varying volumes and stroke characteristics. This allows for the end user to have near infinite adjustability of the system without purchasing additional components, as well as a lighter overall system as the spring element, air, is significantly less dense than steel. However, because stiffness of the air spring is also proportional to temperature, consistent performance cannot be guaranteed over extended time of hardcore use - effectively removing air springs as an option for performance applications.

The Damper

At a fundamental level, the damper serves to absorb the kinetic energy of the suspension motion, in order to control the response of the vehicle. This can be achieved in many ways, but the most common method utilizes hydraulic oil, and its shearing properties, to convert motion into heat.

Primarily, the designer is concerned with adjustability of the damper, its performance across a variety of terrain, and any additional features that are needed to manage extreme events like bottom out. Here the fluid volume also directly relates to potential performance degradation in heavy uses. Further, dampers are sensitive to the leverage ratio of the system, so this must be accounted for.

Industry Benchmarks

When designing a suspension system for a clean-sheet vehicle design, we mustn't fail to utilize the available data from the traditional moto industry. Here, forks and shocks are much larger than their MTB counterparts, linkages are typically utilized for most track and demanding off-road use cases, and dampers utilize more basic valving designs.

As the godfather of the eMoto world, the KTM Freeride E-XC has chosen to take a relatively conservative path for design. Utilizing a direct mount rear shock, and technologies associated with lower levels of performance, the bike strikes a balance of good rideability and cost savings for the broad population.

The Surron Ultra Bee is the newcomer to the midweight eMoto class and their approach is more outside the box. They utilize an inverted linkage design, shocks that are closer to MTB size than moto, and smaller mounting hardware. Because of these choices, one might expect reliability and performance degradation when used in the most aggressive applications.

Finally, for the Stark Varg, as performance (and literal) heavyweight in the eMoto space, their suspension spec is critical. They have chosen to follow the industry by specifying fitments and technologies that match their gas-bike counterparts, as well as linkage design that might look familiar to eagle-eyed consumers.

The Dust Approach

We are developing a mid-weight eMoto designed to lead in performance and fun. We also believe in owners having the opportunity to modify, tune and service their bikes, and so we have decided to take best-in-class methods from the Moto industry, tailored for our application. This means that we are developing custom kinematics for our unique platform using a linkage based design, and leveraging existing fork + shock components/fitments that perform at the highest levels of abuse. Riders can expect kinematics that deliver exceptional traction, bump absorption as well as bottom-out prevention for the biggest hits.

Gold Dust

- Rookie Haiden Deegan and 250 class graduate Jett Lawrence win respective 250 and 450 class SuperMotocross World Championships in LA coliseum. (Here)

- Honda re-factors the iconic 1980s Motocompo as the MotoCompacto, featuring electric drive. (Here)

- And(!) ahead of the Japan Mobility Show, Honda reveals a second new electric scooter inspired by the iconic 1980s Motocampo: the Honda Pocket. (Here)

- Onewheel electric skateboard has issued a voluntary recall on all of its 300k self-balancing vehicles in the US to seek to remedy the products after 4 known deaths: 3 without a helmet. For the newer models a software update with a new warning system is the fix. A “Haptic Buzz” feedback that riders can feel and hear when the vehicle enters an error state, is low on battery, or is nearing its limits and needs to slow down.(Here)

Catch us at newsletter@dustmoto.com OR just respond to this email!

Done and DUSTED for this month. See you all on the next lap.

Member discussion