⚙️ #18 A Symphony of Safety 🦺

Off-road Safety Landscape

Off-road vehicle safety has long been loosely regulated when compared to their road-going counterparts. As shocking as it may sound, the vehicles that we so enjoy riding at high speed, and across punishing terrain oftentimes have fewer regulatory requirements to meet than a typical bicycle.

If this is the case, why are there not frequent cases of vehicles suffering catastrophic failures? Historically, this can be attributed to the steady maturing process that the industry has seen across several decades, as performance levels have increased along with the capability and resource of the key manufacturers. Effectively self governing, these manufacturers understood the importance of not harming their customers if they wished to continue to successfully operate, and so were incentivized to operate internal testing programs limiting the likelihood of failure. Quality and reliability have become key characteristics for the best companies as a result.

However, this "organic system of governance" breaks down during times of dynamic change, where new product categories, technologies, or brands rapidly enter the market injecting numerous unknown unknowns. Further, in a time where new startups are encouraged to "move fast and break things" and our globalized economy drops new products to our shores from all over the world, the incentive of deliberately testing diminishes. Unfortunately this means the customer themselves are exposed to the unexpected risks associated with a lack of regulation. The hover board market and associated regulation is a great example of this dynamic.

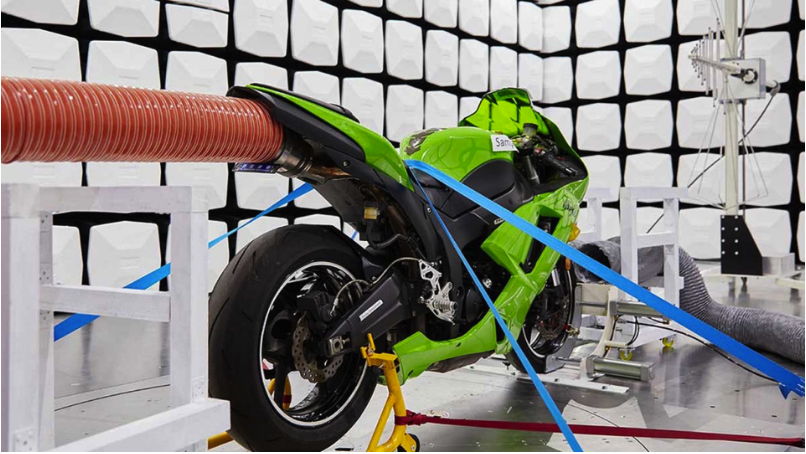

The topic of safety might not be as sexy as suspension or powertrain conversations, but for Dust, it is a key focus in our multi-stage development program. Prototyping allows us the opportunity to learn how our products behave in a wide variety of real world and lab based circumstances, so that when our product ships, we can be confident it will perform for our customers. The market has a long way to go as electric powertrains and OEMs are being brought to market from all over the globe, and we hope to help lead the way.

Safety Standard Basics

At the most basic level, safety standards are enforced through the government of the country where a product is sold. While many countries around the world work to align their standards for ease of commerce and some guarantee of outcome, there still remains a myriad of topics needing to be addressed depending on where the product is sold. These include emissions, physical product safety, electrical safety, material hazards and highway operation standards, among others.

In the case of two wheel vehicles, by far the pinnacle of regulation comes from road-registered vehicles for the European Union. By comparison, "off-road only" bikes sold in America have relatively little practical system requirements to meet to be allowed to be sold; just abstracted requirements around material and radiated emissions.

As a reference, the automotive safety industry is highly evolved, and deeply regulated. Drawing from aerospace, Functional Safety as a topic (ISO 26262) has gained significant traction as a model for developing inherently safe systems for operation in safety critical environments. Its application is technical and onerous, leading to many firms to steer clear, if they have even heard of it.

Does this mean that we should not complete rigorous development and testing for product safety because the requirements don't exist? For many, this might be the case, but for Dust, absolutely not!

Meeting Standards

Ultimately, navigating the regulatory environment for a young startup can be challenging and it is critical to match the effort involved against the business model, in terms of regional sales and investment in test and development. There have been many stories of young companies committing to sell their product all over the world, only to be stymied by the significant time and cost needing to be invested to achieve compliance.

Smart development dictates an accounting of requirements be done against the intended use case of the product and captured in the specification. From there, test plans can be designed and planned within the development program. As the system progresses through prototyping, these tests should be run at both the component and system level for validation of the engineering design, as well as verification that the intended outcomes are achieved.

From there, the pre-production product can be taken to a Nationally Recognized Test Lab (NRTL) to be tested and certified by a 3rd party. In the situation where detailed requirements may not exist to test in specific ways, the OEMs still have the ability to complete testing on their own internal test plans.

Current Issues and the Future of Regulation

Notable issues for the two wheel industry as we navigate a period of significant change:

- Battery system safety, including thermal runaway

- Structural safety as products are operated outside of intended use

- Unintended acceleration and other throttle related failures

- Light Electric Vehicle safe operation at highway speeds

- Performance modifications developed without a systems engineering responsibility

Notably, the gap between a high quality battery pack, and many being sold on the market today is massive. While consumers oftentimes only see the cost side of the decision, it is important for people to understand the potential risks.

The industry has seen its fair share of recalls related to battery safety and vehicle dynamics. It is a shame that the cause of these events come not only from unforeseen or accidental circumstances, but also negligence. These safety related events inevitably draw attention from regulators, and eventually create new compliance demands. While the US market is a ways behind the EU, we believe that things will settle out over the coming years and the barrier to entry for developing both off-road and road going electric motorcycles will only increase.

OEMs that have tight control of their design, testing and manufacturing have an advantage over competition that might be more focused on moving quickly and developing the next copycat product.

The Dust Take

So what is Dust doing to get ahead of these challenges and build the safest possible products?

- Developing a comprehensive test program centered on our phased prototyping schedule. As we progress, numerous bikes and sub-systems will be sacrificed for testing, including being ridden by some of the most abusive pro riders.

- Leveraging state of the art battery system design techniques across enclosure, cell specification, thermal management, connectors, software, and charging.

- Investing in our US operation, to allow for market awareness, quality control, service, and top tier engineering

- Pragmatically selecting compliance targets that match the spirit of the company, as well as set us up for success entering the global market - essentially overshooting whats "needed" to ship bikes in the US.

- Creating a performance specification that leaves less need for under-developed aftermarket powertrain upgrades. Essentially, ship a bike that is amazing for 95+% of the market.

While Dust won't ever be the cheapest bike on the market because of our premium performance positioning, we back up our customer's investment with peace of mind that we have been intentional about safety and quality.

Gold Dust

- Travis Pastrana reviews the Stark Varg and has some really interesting takes on the emoto industry that validate the Dust way of thinking. Check it out HERE

- Here at Dust we love seeing riding in our own home state. Checkout this PinkBike special on 5 day MTB riding session on the Oregon Coast HERE.

- Does pouring money into suspension make it better? Check out this video by Motocross Action where they ride and review a spendy suspension set up HERE.

Catch us at newsletter@dustmoto.com OR just respond to this email!

Done and DUSTED for this month. See you all on the next lap.

Member discussion